Changing and caring for wood furniture makes it look new again and helps it last a long time. Engineered Group offers modern solutions like high-quality wood grain vinyl wraps and special films. These are made to make your furniture look new again, very easily and for a long time. If your furniture has worn finishes, water damage, or old styles, homeowners and designers find Engineered Group’s vinyl wraps a quick and easy solution that creates little waste. This guide will show you our films, how they look like real wood, how they protect, and how to put them on. You’ll get simple DIY steps, care tips, ideas for wood trends in 2025, and how our films compare to paint and veneer. All this is backed by Engineered Group’s knowledge and products.

Look at Engineered Group’s best wood grain vinyl wraps and special films today.

Wood grain vinyl wraps and special films stick to surfaces. They make furniture look and feel like real wood, protect it, and are easy to care for. Engineered Group makes high-quality, strong films. These films have a printed vinyl surface, a textured feel, sticky glue, and a top layer that protects against water and scratches. These films stick to prepared surfaces like solid wood, MDF, melamine, and plywood. They give a smooth look with less waste and are faster to apply than traditional refinishing. Our large catalog helps you pick the best film type and texture for any furniture. It also clearly explains how long it will last and if it can be fixed.

Wood grain vinyl wrap looks like real wood because it has high-quality printed patterns and colors. It also has textures that feel like oak, walnut, or maple. Engineered Group’s modern way of making films gives them a deep look and makes them reflect light like real wood. This makes many surfaces look very real. However, if you look closely, you might see repeated patterns or differences in how it ages compared to real wood. Knowing these small differences helps you understand what to expect regarding how real it looks versus how practical it is.

Furniture vinyl wraps usually have a printed PVC film on top, a textured layer to resist scratches, sticky glue, and a paper backing. Engineered Group’s best special films might have UV protection, thicker layers, and special glues for even better results. They work well on painted or sealed solid wood, MDF, and melamine. The surface needs to be smooth, clean, and strong for the film to stick properly. Choosing films that are known to resist scratches and water, and checking if they work with your surface using Engineered Group’s product details, helps prevent them from failing too soon.

Wood grain vinyl often comes in matte (dull), satin (slightly shiny), and gloss (very shiny) finishes. Each one looks different. Engineered Group offers many textures, from smooth to raised, hand-scraped, or brushed. These make the film feel more real and spread light to hide small flaws. Matte and satin finishes are good for kitchens and bedrooms because they reduce glare and look natural. Glossy finishes work well for modern furniture. Picking the right finish means balancing how it looks, how light hits it, and how easy it is to clean. Engineered Group’s experts can help you choose.

Vinyl wraps quickly update how furniture looks, protect its surface, and are better for the environment than buying new furniture or doing a lot of refinishing. Engineered Group’s vinyl solutions are thin, protective layers. They help stop scratches, spills, and sun fading. They also let you change your furniture’s style a lot without heavy sanding or using strong chemicals. Putting them on takes little time. This means your room isn’t out of use for long, and you can update several pieces of furniture in your home or office step-by-step. This part explains how vinyl protects, how it saves money, and how it helps the environment. These reasons make vinyl a good choice for many homes and businesses, showing how valuable Engineered Group’s products are.

Vinyl wrap provides three primary protective benefits:

These protective features mean you won’t need to refinish your furniture often, and it will last longer. This brings us to how vinyl compares in cost to older methods.

Before looking at the table, check out Engineered Group’s best wood grain vinyl options for many pieces or items used a lot. To make sure the film sticks well, ask a professional installer from Engineered Group’s team to check your surface and help pick the right film.

| Finish Type | Protection Attribute | Typical Lifespan |

|---|---|---|

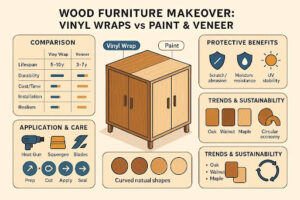

| Vinyl Wrap | Resists scratches, moderate water, UV | 5–10 years with proper care |

| Paint (High-quality) | Protects color; can chip easily | 3–7 years depending on use |

| Veneer | Looks like real wood; can peel off | 10–30+ years if well-bonded |

Vinyl wraps protect furniture by acting as a strong top layer. This layer takes the hits and chemical contact instead of your furniture. Engineered Group’s protective layers and topcoats make the film resist scratches. They often have UV protection, which slows down color fading from the sun. The film covers the surface completely, stopping spills from soaking in. Cleaning regularly and not using strong chemicals keeps the top layer strong. This shows why Engineered Group’s vinyl works well for furniture used often and in wet areas, as long as it’s chosen and cared for correctly.

Vinyl wrap saves money because it needs less work. You don’t have to apply many coats of paint or wait for them to dry. It also creates less waste than veneers or buying new furniture. Engineered Group’s films are easy to put on. For flat surfaces, it can be done in hours, meaning your furniture is ready to use sooner. Vinyl also means you don’t have to remove a lot of the old surface or use many strong chemicals to get it ready. This quick and easy process makes Engineered Group’s vinyl a good choice for updating styles, especially when you need to save money and finish quickly.

Vinyl wrapping helps the environment by making furniture last longer. This means less furniture is thrown away, and we need less new wood and fewer factory resources. Using Engineered Group’s strong films means we don’t use as much energy and resources as making new furniture. Choosing glues with fewer harmful chemicals and making sure installations can be fixed also helps the environment. Making furniture last longer fits with the idea of a ‘circular economy’ and means less trash from homes.

Putting on wood grain vinyl needs careful surface prep, exact measuring, and a step-by-step process using heat and pressure. The key is a clean, smooth surface, cutting precisely, and using heat to set the edges so it sticks for a long time. Engineered Group offers full guides and high-quality films. The tools, steps, and ways to fix problems change depending on the furniture piece. So, you need to adjust the method for different shapes. The sections below cover tools, step-by-step guides, and common problems. All of this is supported by Engineered Group’s product advice.

Before you start, get all your tools and materials ready. This will help you avoid stopping during the install and keep the film straight when working with big pieces. Engineered Group offers special toolkits and top-quality films to help you succeed.

Essential tools for film application:

Having the right tools makes putting on the film easier and lowers the chance of it not sticking. Now, let’s look at the detailed steps.

You’ll need a heat gun, a squeegee with a felt edge, cleaning clothes that don’t leave lint, 70% rubbing alcohol, and razor blades. Other helpful items include edge-sealing glue, primer, a seam roller, and protective gloves. Pick films made for furniture or building use. Check their thickness, how well they resist UV light, and what surfaces they work best on. Engineered Group’s product details explain these things, and experts can help you pick the right film and tools. Choosing correctly helps avoid mistakes and makes sure the finish lasts.

For cabinets and tabletops, first clean and lightly sand the surface. Then, measure and cut the film, leaving a little extra around the edges. Place the film, peeling off part of the paper backing. Use a squeegee to press it down from the middle outwards, pushing out any air. Use a heat gun to make the film fit around edges and corners. Carefully trim off extra film with a straightedge and blade. Then, use heat one last time to make the glue stick firmly. Seal any open edges if needed, and let the glue dry completely. Engineered Group provides detailed video tutorials and written guides.

Common problems are bubbles, edges lifting, bad seams, and wrinkles. These happen if you don’t use enough heat or pull the film too tight. For small bubbles, use heat and a squeegee. For bigger problems, lift the film and put it back down, using primer if needed. If edges lift, using an edge sealant or stronger glue often helps. If fixes don’t work, or for tricky curves or valuable old furniture, think about getting a professional installer from Engineered Group’s approved network. This protects your furniture and its warranty.

Good care keeps both vinyl-wrapped and solid wood furniture looking good and strong, meaning fewer repairs. Cleaning is different: vinyl can handle mild soap and water, but solid wood needs careful moisture and oiling or waxing. Controlling humidity stops veneer from lifting and wood from moving. Using protective items reduces everyday wear and tear. The sections below explain how to clean, protect, and decide when to refinish or restore. All this applies to furniture updated with Engineered Group’s films.

Clean vinyl-wrapped furniture with gentle, pH-neutral soap mixed in water. Use a soft microfiber cloth. Don’t use strong chemical cleaners, rough pads, or pure alcohol. These can harm the glue or film layers. For spots, gently lift the film edge if you need to clean under it. Or, fix small lifts by using heat and a squeegee. Cleaning gently often and quickly wiping up spills makes the film look good longer and keeps it sticking well. Engineered Group suggests certain cleaning products that work well with their films. These steps keep the film looking good and protecting your furniture.

Protect wood and wrapped surfaces with coasters, placemats, and hot pads to stop heat and water. Use felt pads under heavy items. Keep the air’s moisture level (humidity) between 40–55% to stop wood from changing shape. For surfaces used a lot, think about clear protective mats or putting oil/sealant on solid wood from time to time. Make sure Engineered Group’s vinyl-wrapped surfaces are not exposed to high heat for too long. Always protecting your furniture means you won’t need to refinish it as often.

Refinish or restore furniture if it has broken parts, deep cuts, loose joints, or a lot of missing veneer. Also, if the furniture is valuable enough for a professional to fix it. Simple restoration means fixing broken parts, sanding, matching colors, and sealing. Old, valuable items might need special care to preserve them. For wrapped items, see if it’s cheaper to fix small areas, re-wrap the whole thing, or replace the film completely. Engineered Group gives advice on fixing or replacing film. For old or valuable items, ask an expert to keep them in good condition.

What people choose and what’s popular in design affects how you renovate and what wood grain patterns you pick for vinyl. Popular woods like oak, walnut, and maple are still liked. Wood that is recycled or comes from sustainable sources is becoming more popular. In 2025, design trends focus on natural shapes, finishes that look natural, styles from the mid-1900s, curved lines, and mixing different materials. This section describes common woods and trends. It shows how Engineered Group’s wide range of products fits with changing styles.

To compare characteristics and typical uses for common species, the table below maps wood types to grain character, common uses, cost range, and sustainability notes for quick decision-making.

| Wood Type | Grain Character | Common Uses | Sustainability Notes |

|---|---|---|---|

| Oak | Clear, open grain | Tables, cabinets, floors | Widely available; choose certified or recycled when possible |

| Walnut | Rich, straight to curly grain | Fine furniture, thin wood layers | More expensive; recycled or certified sources preferred |

| Maple | Tight, smooth grain | Drawers, cutting boards, modern furniture | Strong and useful; engineered options create less waste |

Hardwoods like oak, walnut, and maple are valued for being strong, having nice grain, and being useful for both everyday and fancy furniture. Softer woods like pine are cheaper for country-style or painted furniture. Engineered options (like plywood, MDF with thin wood layers) are stable and create less waste. Your choice depends on how you’ll use it, your budget, and how you want it to look. Engineered Group has vinyl options that look like all these wood types.

Top trends for 2025 include curved or natural shapes, surfaces that look natural or not too shiny, and a new interest in old-fashioned or mid-century styles using modern materials. Designers are more and more mixing wood with metal or fabric for furniture that uses different materials. These trends affect which vinyl patterns you choose (like warm oak, dark walnut, light maple) for a matching update. Engineered Group’s large catalog has the perfect match for any trend.

Being eco-friendly makes buyers choose wood that is certified (FSC), recycled, and finishes with fewer harmful chemicals. It also encourages fixing and extending furniture life, like with wrapping. Buyers care about the whole life of a product. They compare how long it lasts and if it can be fixed against its environmental impact. Taking care of furniture and using certified or recycled materials lowers harm to the environment. Engineered Group’s vinyl wraps are an eco-friendly choice. They make furniture last longer and mean we need fewer new resources.

Comparing vinyl wrap with paint and wood veneer helps you understand the pros and cons of how they look, cost, last, and are put on. Engineered Group’s vinyl solutions have consistent patterns, textured choices, and are quick to install. Paint offers endless colors and can be easily touched up. Veneer looks like real wood but needs careful gluing and can peel off. Your choice depends on the furniture’s value, shape, and how long you want it to last. Engineered Group offers better performance and many style options.

| Method | Cost & Time | Durability | Installation Difficulty | Aesthetic |

|---|---|---|---|---|

| Vinyl Wrap | Low–medium cost; fast install | Medium (5–10 yrs) | Medium; needs heat/skill for curves | Consistent wood patterns; textured options |

| Paint | Low cost; longer dry times | Changes; can chip easily | Low; simple but needs prep | Unlimited colors; less wood realism |

| Veneer | Medium–high cost; skilled install | High if bonded; risk of peeling | High; needs precise work | Most realistic wood appearance |

Engineered Group’s vinyl wraps are reliably strong on the surface and look like textured wood. They resist spills and scuffs. Paint can chip, but it’s easy to fix small spots. Veneer looks like real wood, but it can peel off. How it looks depends on balancing realness versus care: veneer for a truly real look, paint for many color choices, and Engineered Group’s vinyl for a quick, affordable, and realistic style change.

Costs depend on the price of materials, how much work is needed, and how long the furniture is out of use. Paint materials are cheap, but it takes more work and time to dry. Veneer costs more for materials and needs more skill to apply. Engineered Group’s vinyl uses good materials and needs a fair amount of work, but it finishes faster. How hard it is to install depends on the shape of the surface. Flat surfaces are cheap, but curves take more time and skill. Your budget, time, and what you expect the final look to be will guide your choice. Engineered Group offers clear prices and expert advice.

Do it yourself with vinyl wrap for simple, flat surfaces and small projects if you have the tools and patience. Choose professional installation for big panels, tricky curves, valuable old furniture, or business uses where guarantees and perfect sticking are very important. Engineered Group can connect you with approved professional installers. They can help check your surface and pick the right film for busy areas, lowering the chance of problems.

Answering common questions simply helps readers know what to expect about how long vinyl lasts, what it works with, how to fix it, and how to care for both wrapped and solid wood furniture. Short, clear answers give the main facts and point to more detailed steps in earlier sections for fixing or caring for furniture. The questions below give quick answers to help you make practical choices and offer final advice, including where to get products or find installers. All this is based on Engineered Group’s product knowledge.

Furniture vinyl wrap usually lasts 5–10 years if put on and cared for well. Better films or professional installation can make it last longer. How long it lasts depends on how much it’s used, how much sun it gets, how well it sticks, and how you care for it. Quickly fixing lifting edges and not exposing it to high heat for too long helps the glue stick. If you need it to last a very long time, pick higher-quality special films from Engineered Group and think about professional installation.

Yes, you can put vinyl on real wood furniture if the surface is clean, strong, and smooth (no deep cuts or loose veneer). Good preparation is a must. Small fixes like filling cracks, sanding shiny finishes, and using primer make the surface perfect for the film. If there’s a lot of damage or the furniture is old and valuable, restoring it might be a better choice. Good preparation and testing a small spot lowers the chance of the film not sticking. Engineered Group offers primers and advice for the best sticking.

You can fix small bubbles by heating and pressing them with a squeegee. Bigger bubbles might need you to lift the film and put it back down with primer. If edges peel, you often need to clean, re-glue, and seal them. If they keep peeling, it means there’s a problem with the surface or the glue. If spills cause discoloration, use mild cleaners. If it can’t be fixed, you might need to replace that part of the film. For repairs that are too big for simple fixes, or for valuable furniture, get a professional opinion or check Engineered Group’s help resources.

Care for solid wood by dusting it often, keeping humidity steady, and using the right polish or oil. Don’t let water sit on it or use strong chemicals. Fix scratches with markers or light sanding and re-sealing. For a lot of wear, think about professional refinishing. Using coasters, felt pads, and checking humidity often means you’ll need fewer repairs. For big changes or guaranteed results, look at Engineered Group’s best wood grain vinyl options or ask a professional installer from their team to p out the best way to go.

Contact Our Experts View Our Products

Whether you like to do things yourself or need a professional, Engineered Group has the high-quality wood grain vinyl wraps and knowledge to make your ideas real. Look at our products, find an installer, or get personal advice today.